REMAX STEAM TRAP INSPECTION SYSTEM

STEAM TRAPS INSPECTION

The aim of steam trap surveys is to detect problems like steam leaks, low energy efficiency, flooding, inappropriate design or sizing, defective assembly, inadequate discharge temperatures, high back pressure, obstructions, blockages, water hammering, etc.

Usually more than 20% of steam traps leak live steam, what is incompatible with rational use of energy, sustainable growth and fight with Climate Change. The establishment of an effective program of inspection and predictive, preventive and corrective maintenance considerably reduces all the mentioned incidents and is especially useful to reduce steam leaks, optimize energy efficiency and reduce the emission of greenhouse gases in steam networks. The table shows indicative values of incidents in purge stations in correspondence with the frequency of inspection and maintenance.

INSPECTION BY REMOTE MONITORING – CATS (complete automatic traps surveying)

This is the most reliable method since unlike the rest, where only the situation is assessed at a given time, the monitoring takes into account the evolution of the parameters that define the operation of the trap over time, identifying substantial changes that they are clear indicators of failures or anomalies.

The monitoring can be total or partial depending on the parameters monitored: ultrasound, temperature, and back pressure. For more information

DESIGNING STEAM TRAPS MONITORING SYSTEM

The design of data transmission topology is one of the most critical aspects on steam traps monitoring systems. Data transmission can be done via cable, wireless, optical fiber, etc. If the wireless option is chosen, a 3D previous analysis of wireless coverage and of reduction of Fresnel zones should be performed, lack of such analysis almost always leads to failure of the wireless system. Besides, following critical aspects mus be taken into account:

- Line-of-site between antennas

- Density of obstacles between antennas

- Proximity of antennas to the ground (strongly affects Fresnel Zone)

- Access Point or Routing Capacity

In case of large population of steam traps and high obstacles density (i.eg. petrochemical plants) wireless range distance must be reduced to 30 – 40 meters to guarantee data transmissions from Wireless Devices to Access Points. Once the structure of Access Points has been designed (without exceeding their maximum capacity), their power lines and data lines (electrical wiring, and optical fiber to its Gateway) must be designed. The most serious and frequent error in wireless topology design is due to not installing enough Access Points. Correcting this deficit during startup generates large extra costs.

CATS TOPOLOGY

CATS topology offers extraordinary flexibility by combining wired & wireless architectures to easily adapt to any industrial environment. Its high reliability and scalability allows monitoring tens of thousands of steam traps in a single monitoring network and platform, reducing installation costs and maintenance.

The REMAX ENERGY steam traps monitoring system combines innovative technologies (digitization, sensitization, acquisition and data processing, …) to perform accurate real-time steam traps failure diagnostics in order to achieve 10% to 30% steam saving by applying the Intensive Maintenance Methodology on huge population of steam traps

REMAX Steam traps surveying software(RTMS):

A steam trap survey is essential to find leaking or faulty traps and offer significant savings for the customer. With conventional steam traps, once fitted they could begin leaking anytime from the same day to six months later. Without regular testing, leaks would be impossible to determine.

A failed open (leaking) steam trap on a 145 psig steam line, will cost up to an additional US$ 2,000 per year. Thus, for a site with 100 units, with a conservative failure rate of 15%, the additional cost due to wastage would cost US$ 30,000 per year in unnecessary steam losses.

Leaking steam systems are tremendously inefficient. It’s like trying to heat your home with the windows open.

REMAX have steam survey engineers ready and equipped to test, analyse and find these leaking units and using proprietary software based REMAX Trap Management System (RTMS), they are able to accurately interpret the Thermovision and ultrasonic readings to provide a detailed report showing:

Pounds or kilograms of steam lost per trap, per annum

Cost of steam lost in local currency

Carbon Dioxide (CO2) emissions

Steam trap lifespan

Maintenance costs

The REMAX steam survey software provides valuable information allowing calculated decisions to be made relating to:

Maintenance

Energy

Finance

Purchasing

Emission monitoring

Repair plan

Calculation

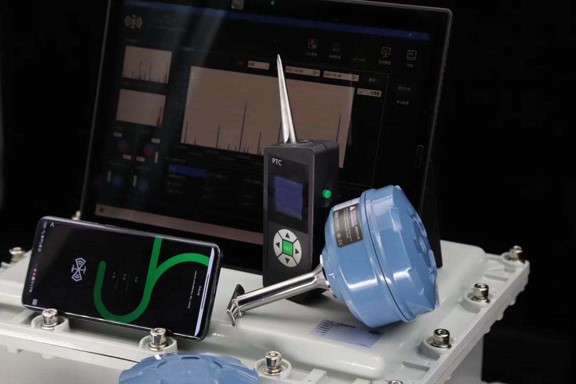

RTT300/RTT300+

The second way to input data to software is handheld trap tester named RTT300 and RTT300+. It need to operator go to the site and test traps one by one with the device. RTT300 and RTT300+ operation is to easy and every operator without complete information about steam traps testing process could use this device because this is completely an automatic device and the operator just need to know how the device work. RTT series include an infrared thermovision camera and ultrasonic sensor to find exact data from each steam trap. The RTT300 series could to save every trap location with 1.5cm accuracy and the operators could to find each trap location easily and also could to check steam trap history test resault. This device could show the steam trap leaking percentage and offer to operators to repair or change damaged traps. RTT series could to share information with server computer and to any computer that you define. Both models(RTT300/RTT300+) are explosion proof and the grade could be customized upon request